The plate heat exchanger unit automatically converts the heat obtained from the primary network into the domestic water and heating water required by the user. That is, the hot water (or steam) enters the plate heat exchanger from the primary side inlet of the unit for heat exchange, and then flows out from the primary side outlet of the unit; the secondary side returning water passes through the filter to remove the dirt, and then enters the plate through the secondary side circulating water pump. The heat exchanger performs heat exchange to produce hot water for different temperatures such as heating, air conditioning or floor heating to meet the needs of users.

FLFA heat exchanger unit function (selectable according to user needs)

1. Temperature regulation control: The circulating water flow rate is constant, and the heating temperature is automatically adjusted according to the ambient temperature change, so that the heat supply is matched with the system load to save heat energy.

2. Flow regulation control: The heating temperature is constant, and the circulating water flow is automatically adjusted according to the ambient temperature change and the supply and return water pressure difference, so that the heat supply is matched with the system load to save energy.

3. Hydration pressure control: The pressure sensor automatically starts and stops the water pump or adjusts the speed of the water pump to stabilize the system pressure according to the measured system pressure according to the measured system pressure, to ensure the safety of the heat and maintain the normal operation of the system. The pressure control range is determined according to design requirements.

4. Condensate recovery control: The liquid level controller automatically turns on and off the condensate pump according to the level change of the tank level to automatically send the condensate back to the boiler room for recycling, reducing the waste of softened water and heat. The condensed water level control range has been shipped from the factory. determine.

Characteristics of FLFA heat exchanger unit

1. Intelligent control, complete control functions, high control precision, stable and reliable operation.

2. The unit adjusts the heat source and hot water supply according to the ambient temperature, primary and secondary pipe network temperature, pressure and other parameters, and has obvious saving effect on heat energy and electric energy during system operation.

3. The system components are highly reliable, and the heat exchanger is a high-efficiency plate heat exchanger. The main intelligent components are imported, which is stable and reliable in operation and durable.

4. Automatic control of system pressure, temperature or flow, intelligent, high degree of automation and easy to operate.

5. It can be monitored remotely, and manual and automatic switching can also be performed.

6. Unattended units can also be operated on-site without on-duty personnel and monitored directly by remote.

7. The unit layout is reasonable, the structure is compact, the floor space is small, the capital investment is saved, the installation and maintenance are convenient, and it is suitable for various heating occasions and heating requirements.

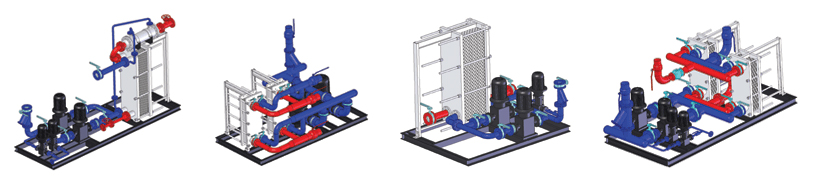

C1 heat exchanger unit

Control function: automatic variable frequency constant pressure water supply function, automatic drainage pressure relief, temperature control.

Specific configuration: secondary side return pipe is equipped with pressure sensor and drain solenoid valve. Secondary side water supply temperature sensor, primary side electric control valve.

Display mode: parameters displayed by the on-site controller: secondary side return water pressure, secondary side drain pressure. Secondary water supply temperature.

Control mode: The field controller automatically controls the variable frequency operation of the make-up water pump according to the secondary side return water pressure, constant secondary network system pressure, and overpressure water discharge. The field controller adjusts the flow rate of the primary side according to the opening degree of the primary side water supply temperature sensor to control the opening degree of the primary side water supply temperature to change the secondary side water supply temperature.

C2 heat exchanger unit

Control function: temperature control function, variable frequency constant pressure water supply function, automatic drainage pressure relief, variable frequency constant pressure water supply.

Specific configuration: primary side: electric control valve. Secondary side: water supply temperature sensor, pressure transmitter, return water pressure transmitter, drain solenoid valve.

Display mode: parameters displayed by the on-site controller: secondary side water supply temperature, pressure and return water pressure.

Control mode: The field controller adjusts the flow rate of the primary side according to the opening degree of the primary side water supply temperature sensor to control the primary side water supply temperature to change the secondary side water supply temperature. According to the secondary side return water pressure, the variable frequency operation of the make-up water pump is automatically controlled, the pressure of the secondary network system is constant, and the pressure is exceeded. The secondary water supply pressure is constant and the secondary side outlet pressure is collected.

C3 heat exchanger unit

Control functions: temperature control function, outdoor temperature compensation function, water pump frequency conversion automatic constant pressure water control, automatic drainage pressure relief, circulating pump frequency conversion system.

Specific configuration: primary side: electric regulating valve, water supply temperature sensor, return water temperature sensor, water supply pressure transmitter, return water pressure transmitter. Secondary side: water supply temperature sensor, return water temperature sensor, water supply pressure transmitter, return water pressure transmitter, drain solenoid valve. Outdoor temperature sensor.

Display mode: parameters displayed by the on-site controller: primary side inlet water temperature and return water temperature, primary side water supply pressure and return water pressure, secondary side water supply temperature and return water temperature, secondary water supply pressure and return water pressure, Outdoor temperature. Has a communication function.

Control mode: The field controller adjusts the flow rate of the primary side according to the opening degree of the primary side water supply temperature sensor to adjust the flow rate of the primary side to change the secondary side water supply temperature, and can also adjust the water supply temperature of the secondary side according to the change of the outdoor temperature curve.

According to the secondary side return water pressure, the variable frequency operation of the make-up water pump is automatically controlled, the pressure of the secondary network system is constant, and the pressure is exceeded. The secondary water supply pressure is constant and the secondary side outlet pressure is collected. When the secondary side return water pressure is too low, the circulating protection pump is stopped to prevent the water pump motor from being burnt by idling. The secondary side pressure is too high to stop the user's outer pipe network to prevent the pressure from being too high to cause the geothermal pipe or the radiator to burst.

C4 heat exchanger unit

Control functions: temperature control function, outdoor temperature compensation function, water pump frequency conversion automatic constant pressure water supply control, automatic drainage pressure relief, circulating pump frequency conversion system, heat metering, hydration flow metering.

Specific configuration: primary side: electric regulating valve, water supply temperature sensor, return water temperature sensor, water supply pressure transmitter, return water pressure transmitter, flow sensor. Secondary side: water supply temperature sensor, return water temperature sensor, water supply pressure transmitter, return water pressure transmitter, drain solenoid valve, hydration flow sensor. Outdoor temperature sensor.

Display mode: parameters displayed by the on-site controller: primary side inlet water temperature and return water temperature, primary side water supply pressure and return water pressure, primary network heat or flow. Secondary side water supply temperature and return water temperature, secondary water supply pressure and return water pressure, outdoor temperature, and water supply flow rate. Has a communication function.

Control mode: The field controller adjusts the flow rate of the primary side according to the opening degree of the primary side water supply temperature sensor to control the primary side water supply temperature to change the secondary side water supply temperature. It is also possible to adjust the water supply temperature of the secondary side according to the change of the outdoor temperature curve. According to the secondary side return water pressure, the variable frequency operation of the make-up water pump is automatically controlled, the pressure of the secondary network system is constant, and the pressure is exceeded. The secondary water supply pressure is constant and the secondary side outlet pressure is collected. When the secondary side return water pressure is too low, stop the circulating pump to prevent the idling pump from burning the pump motor. The secondary side pressure is too high to stop the user's outer pipe network to prevent the pressure from being too high to cause the geothermal pipe or the radiator to burst. Through the hot meter on the primary side, you can know the amount of heat used in a year, and the timely flow. Through the water replenishing flowmeter, we can know the amount of water lost per day in the outer pipe network, and also accumulate the amount of water lost throughout the year.