Our FLFA shell and tube heat exchangers are ideal for condensing and steam heating. An all-welded plate pack makes the heat exchanger ideal for handling aggressive media, as well as high pressure levels and temperatures. With less space requirements and light weight, they are a good alternative to shell and tube heat exchangers.

Product description

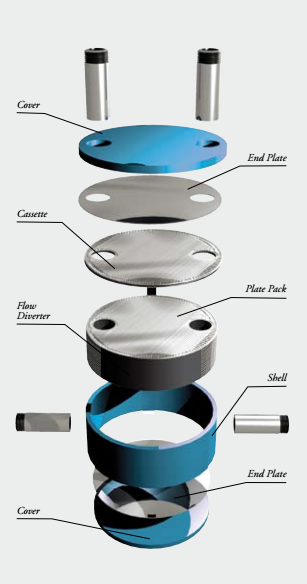

Plate and shell heat exchanger

Our FLFA plate and shell heat exchanger combines the advantages of shell and tube heat exchangers and plate heat exchangers to maintain the high working pressure and temperature of the former and has high efficiency. The “best of both worlds” solution, our plate and shell heat exchangers provide good performance for a wide range of applications, especially steam condensation.

What does this mean for you?

Our plate and shell heat exchangers are available in fully welded plate packs and are ideal for handling aggressive media as well as high pressures and temperatures. Using flat technology instead of piping, the high heat transfer coefficient allows our engineers to reduce the surface area required for performance. The result is a compact heat exchanger that outperforms the shell and tube type, enabling tight temperature access while requiring less space and light weight.

The use of flat panel technology also mitigates the common challenge of shell and tube heat exchangers - dirt. As turbulence increases, the risk of fouling is greatly reduced because turbulence prevents particles and membranes from clogging the heat exchanger.

Compared to shell and tube heat exchangers, FLFA shell and tube heat exchangers are an economically competitive solution that provides a fast return on investment. Small size, light weight, and low installation cost keep the initial purchase price low, especially when special materials are required. Infrequent demand for maintenance and energy optimization performance limits ongoing operating expenses.

Resolve traffic differences

Some apps use different traffic for both media and can solve problems very challengingly. Our asymmetric plate mode is perfect for such applications because they have narrow passages on one side and wide passages on the other. This design allows the heat exchanger to handle different flows easily, allowing us to use pressure drops in an efficient manner, resulting in high turbulence, large heat transfer, and cost-effective operation. Asymmetric mode is a solution for handling high viscosity media or large volumes of compressed gas.

Features and benefits

A highly adaptable heat exchanger. This is a good choice for handling condensate, especially if there is no condensate cooling. They are also perfect steam heaters for cleaning liquids, demineralized water and cleaning hot oils.

The heat exchanger is designed to be highly resistant to thermal shock and thermal stress fatigue, making it ideal for cycle duties and other tasks in sudden large fluctuations in temperature.

Available in both bolted and all welded versions. The fully welded type can withstand higher temperatures and pressure levels than the bolt type, but does not open the wash. This can be done with a CIP (In-Place Cleaning) system.